Concrete Canvas; soft like fabric, hard as a rock!

For those of you who haven’t heard about concrete canvas before, fasten your seatbelt because this is wild!

There’s not a single soul who doesn’t know about concrete and how fundamental it is to the modern human existence. What some might not know, is that there is genious invention called Concrete Canvas.

Concrete canvas looks like a thick piece of cloth, a loose, flapping around grey carpet, but spray some water on it and wait 24 hours, and you’ve got yourself a hard concrete surface!

The composition of CC

In 2004, William Crawford and Peter Brewin from Wales, developed a concept for creating rapidly deployable shelters for humanitarian disaster relief. The concept was an inflatable formwork shelter with a cement-filled geotextile lining that was delivered to site folded within a crate. On site it would unfold using an inflatable plastic membrane, hydrated and within hours the shelter would be ready for inhabitation.

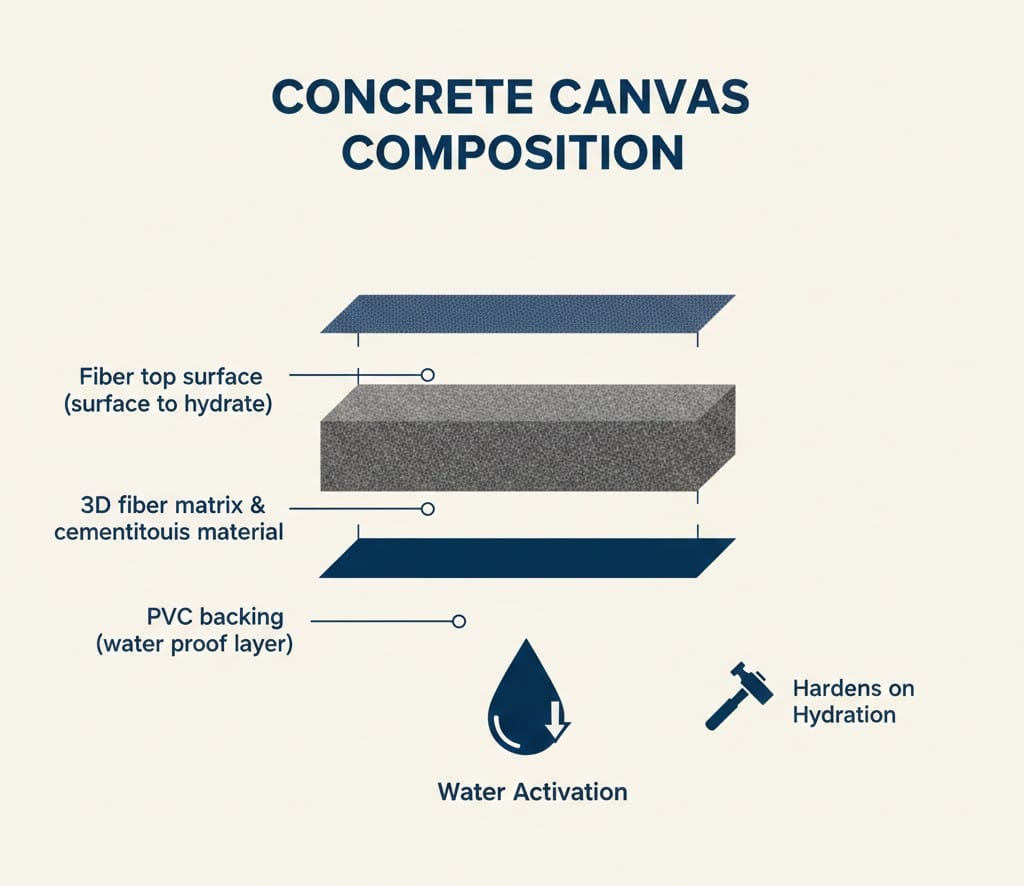

Concrete canvas (CC) consists of a 3-dimensitonal fibre matrix containing a specially formulated dry cementitious mix. A PVC backing ensures the CC is completely waterproof. It can be hydrated by spraying water on it, or by full immersion into water. Water mixes with the cementitious mix and the hardering process begins. Once set, the fibre matrix reinforce the cementitious mix which prevents the formation of cracks.1

Concrete canvas provides a thin, waterproof and low carbon alternative to traditional concrete, but what does this really mean for construction?

A success story that started with a disaster relief shelter, Concrete Canvas has over time developed into applications such as; Channel lining, Slope protection, Bund lining, Concrete repair, Culvert lining, Weed control, Lagoon lining, Gabion protection and more.2

The material can be installed up to 10 times faster than conventional concrete and offers a 95% material saving, which translates to a typical 60% cost saving.3 It makes it possible to cut down manpower & working time on large scale projects (as well as carbon emissions), it’s ideal for remote or logistically challenging projects as it’s easier (and cheaper) to transport than regular concrete and provides fast, durable solutions in line with ISO, ASTM and BS standards - this material surely is a game changer.

We’ve seen the artistic works of Marc Leschelier, we’ve it be used for erosion control, duct linings and such, the concrete carpet has even been translated into furtniture 4, but is there a potential for the material in the field of architecture other than disaster relief? Could it be used to create durable, efficient, inhabitable beauty?

The research paper Review on the design and application of concrete canvas reinforced with spacer fabric5 indicates that structural testing of the material show good promises, but application of concrete canvas and the testing of its properties in a broader scope remains uncharted territory. Because of the carbon-efficiency and potential benefits are great, they highlight that further testing of the material is of great value, but so far we just don’t know enough.

Architecture and construction is a slow moving field. Getting materials tested and approved for various standards, be it structural, environmental, fire exposure or other, is an expensive and tedious process. What we are currently witnessing are the avant gardes of Concrete Canvas dipping their toes in the waters, trying it out in small scale and safe spaces, but who knows what the future brings? Will we see an efficiency revolution within the built environment in the near future? Will we soon be living in concrete houses that takes 10x faster to build?6 I don’t know, but the idea is surely exciting. Perhaps architectural history is in the making, the question is - will you be a part of it?

That’s all from this weeks deep dive!

-Johan

Bibliography

1 https://www.concretecanvas.com/concretecanvas/

2 https://www.concretecanvas.com/application-overview/

3 https://www.azom.com/article.aspx?ArticleID=13415

5 https://journals.sagepub.com/doi/pdf/10.1177/15589250231152591